Infrastructure

Manufacturing Facilities

We specialize in High-Precision CNC Turning & Milling components. At our manufacturing facility in Faridabad, Haryana, we use the latest CNC technology and software to produce precise components in a wide range of materials, including aluminum, brass, copper, steel, and plastics.

Our CNC services include a range of processes, such as machining, threading, drilling, cutting, and shaping, along with operations like deburring, and finishing. We also offer design assistance and can help you optimize your designs for manufacturability and cost-effectiveness. Here at BES, we prioritize quality and efficiency in every project we undertake.

CNC Lathe Machines (03 Nos.)

| Maximum Turning Diameter | 320 mm |

| Maximum Turning Length | 500 mm |

Vertical Milling Machines (4-Axis with Rotary Table)

| Pallet Size | 1000 x 450 mm |

| Z – Axis Travel | 500 mm |

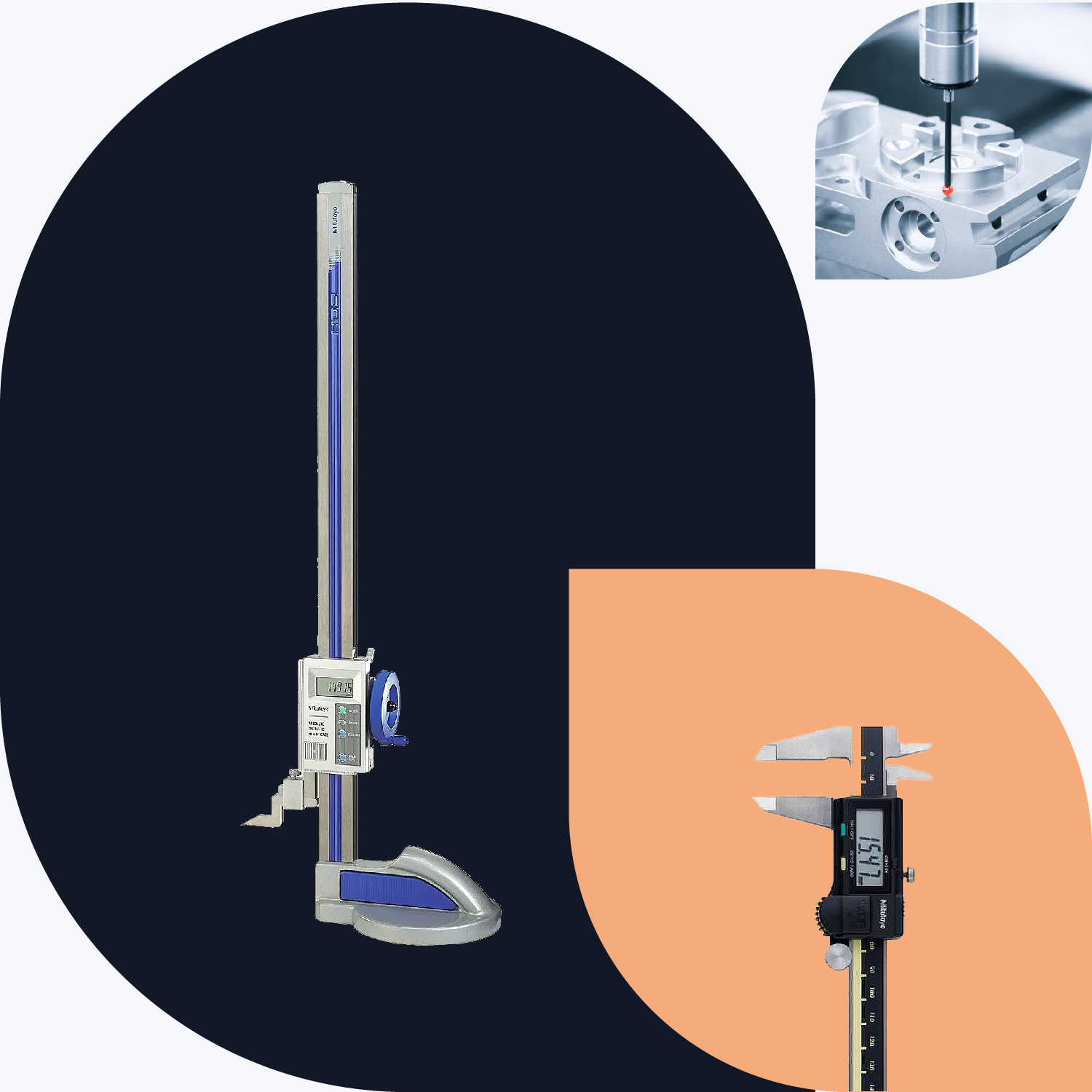

Quality Control

Achieving precision at the micron level demands strict quality control and precise measurement techniques. We are committed to continuously upgrading our measurement and monitoring technology to maintain the highest standards. Our comprehensive system covers all aspects of the production process, from selecting vendors and material IQA to final dispatch, and ensures the use of suitable materials, machines, tools, gauges, and inspection systems. This approach is designed to guarantee that our customers’ expectations are always met.

Our components meet or exceed the standard International quality checks to ensure seamless application/ assembly of parts from different vendors.

We have all the Standard quality control gauges along with component specific gauges.