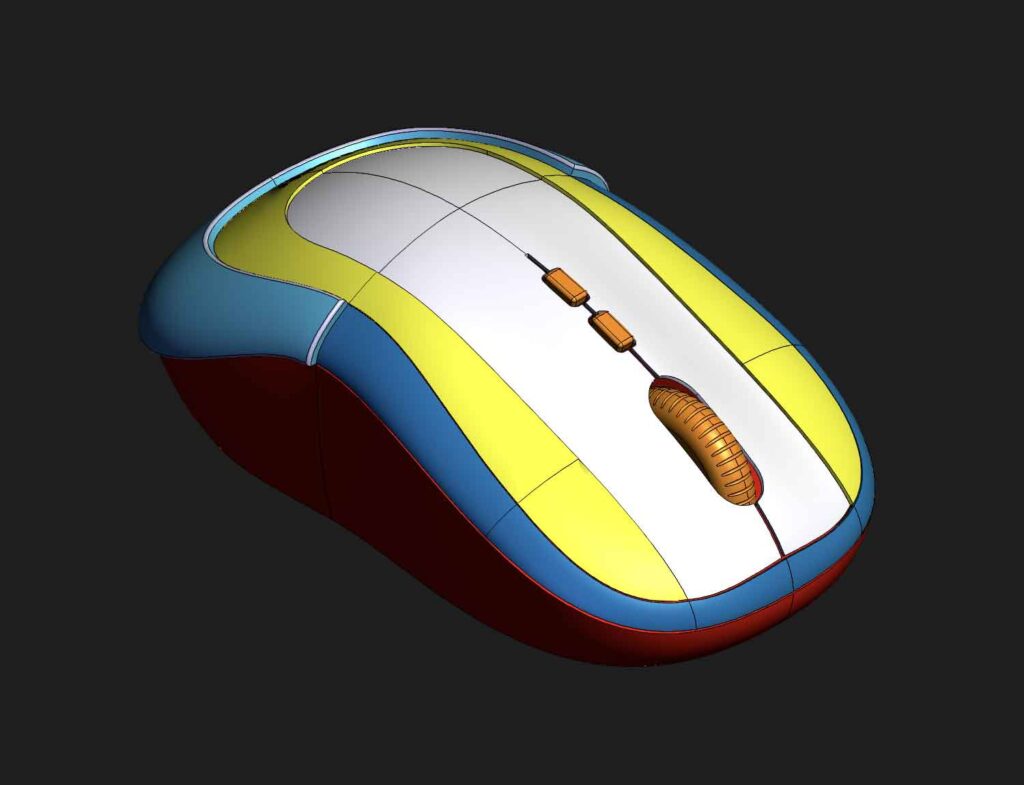

* Die-Mold Manufacturing *

World-Class Die-Molds for a wide array of industrial & consumer products

For streamline product development, improved accuracy, and accelerated time-to-market.

High Quality - High Performance

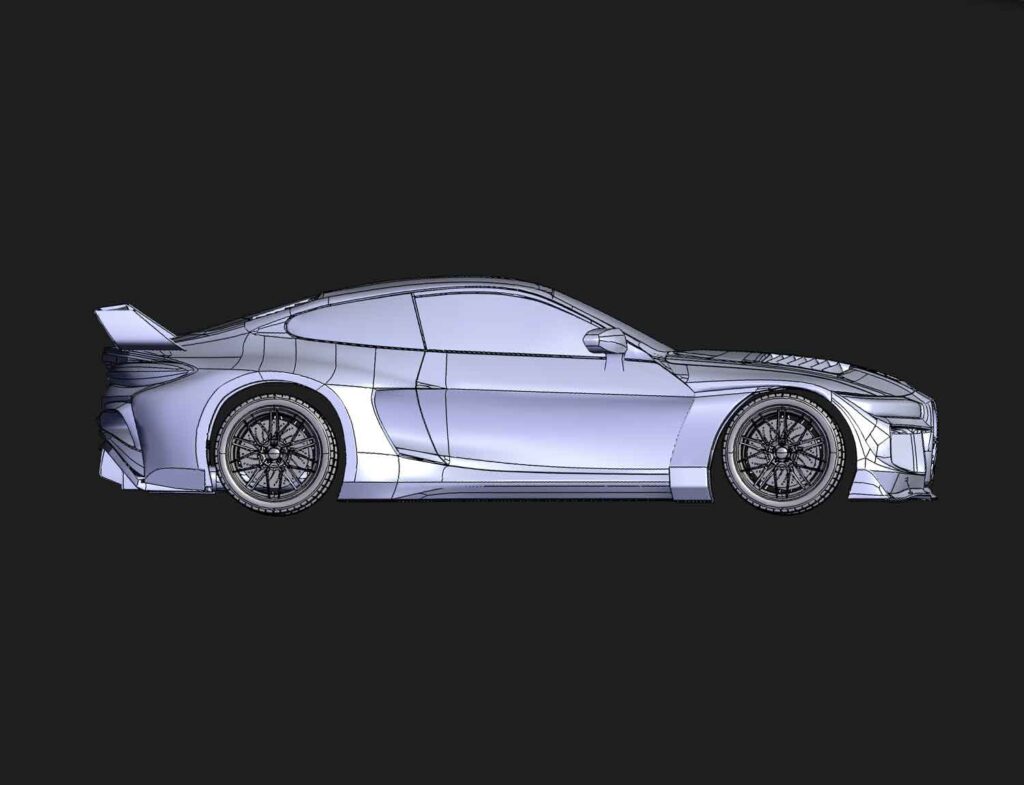

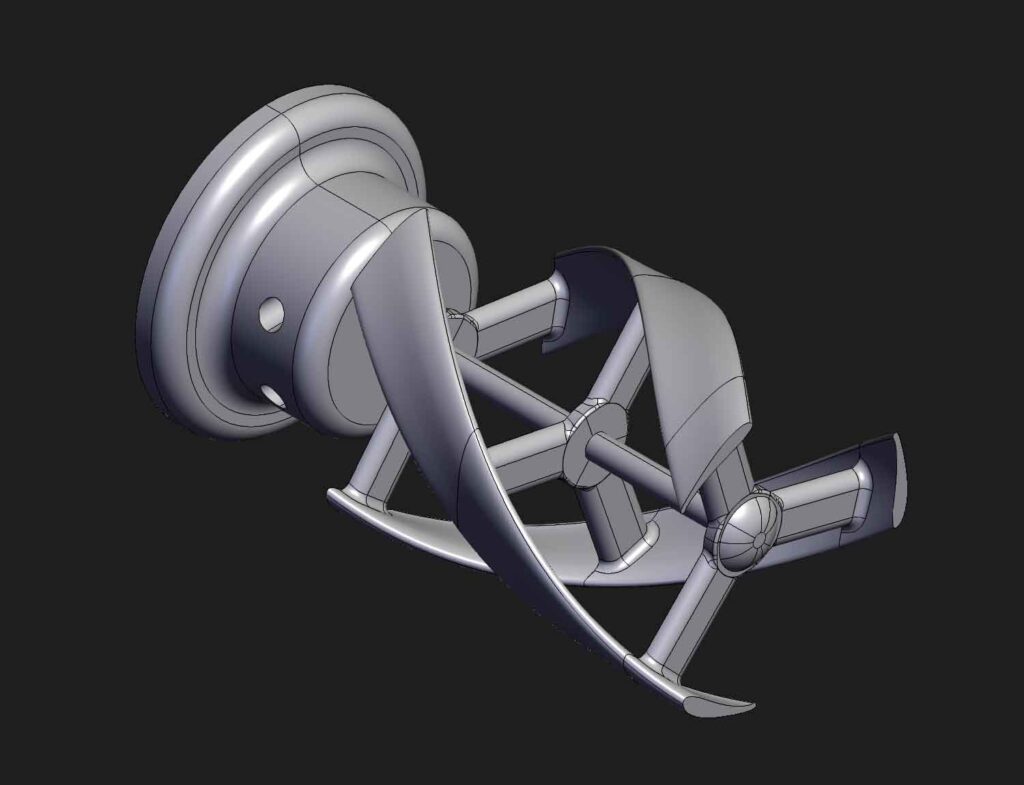

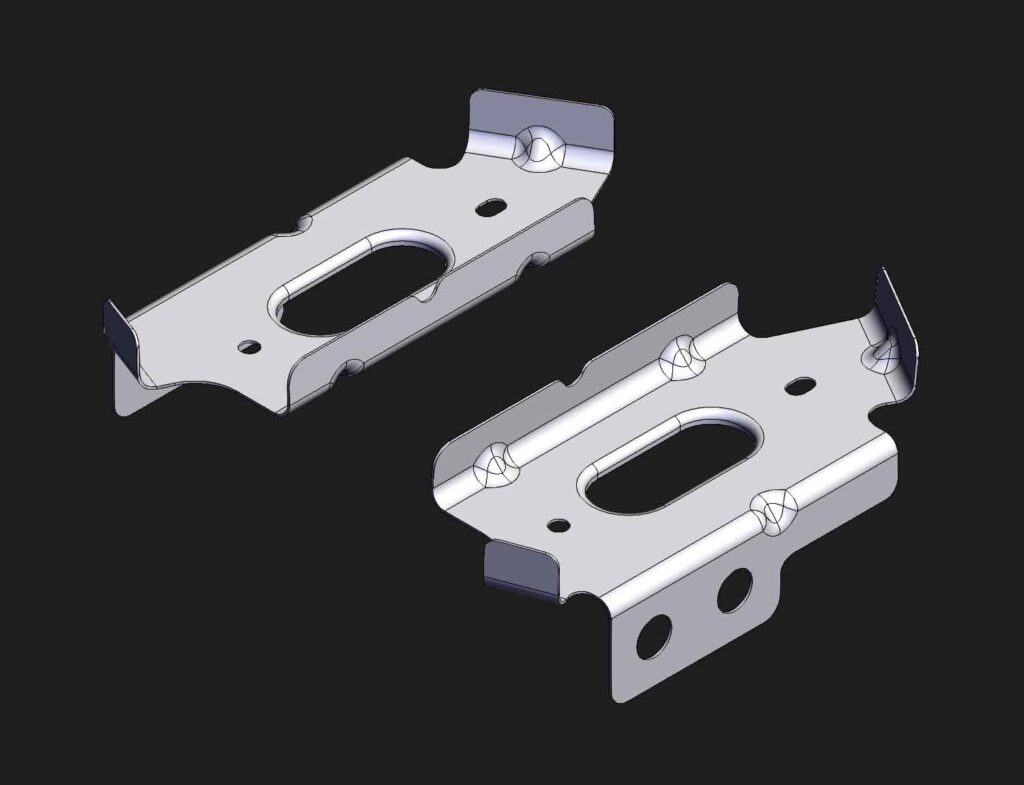

These tools are crucial components in the manufacturing process, with molds being utilized in processes like injection molding and casting, while dies are mainly used in stamping sheet metal and other metals.

Production & Materials

Dies are designed to shape metal sheets and other metal forms into the required shape, with the manufacturing of automotive body parts being a typical application. On the other hand, molds are primarily used in injection molding, shaping melted resin, or casting molten metal into the desired form.

Die molds are typically made from hardened steel and are designed to withstand the high pressure and temperatures required for the molding process. The process of creating a die mold involves a high level of precision and expertise.

At Babra Engineering Services, we are committed to providing high-accuracy Die-Mold services that meet high standards. Whether you need a custom mold designed from scratch or maintenance and repair services for an existing mold, our team has the expertise and experience to deliver results.

Manufacturing Process & Features

One of the key benefits of working with us, is the ability to customize molds to meet specific requirements.

For the finished product, we also offer Heat Treatment for Alloys, Hard Chrome Plating on molds for corrosive plastic like CPVC, PVC engineering plastics etc. And surface finishing like Sand or Shot Blast, Chemical etching on Molds and parts.

Mould Machining

Shaping and designing of plastic, pressure die casting, components by understanding specific needs of the customer.

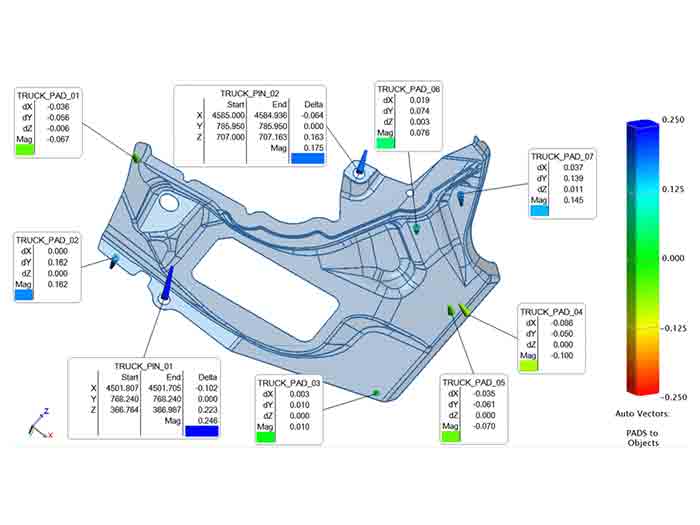

3D Scanning & Reverse Engineering

Present virtual assembly of complex in 3D reverse engineering of components using 3D light scanner.

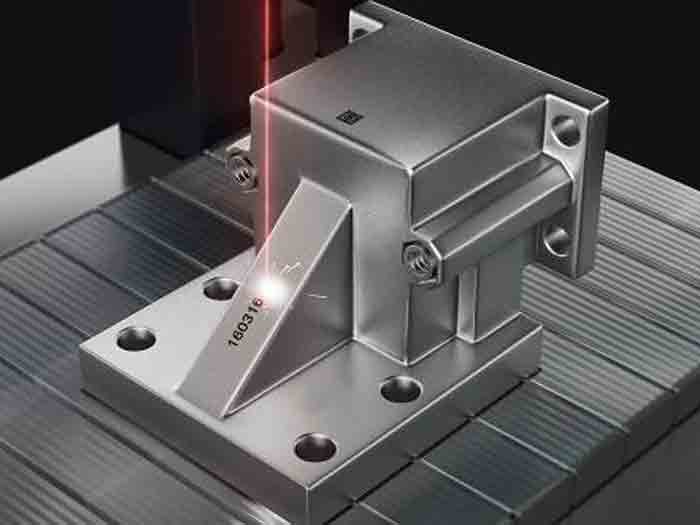

3D CNC Laser engraving for work logo and other marking on Moulds and machined parts.

Full Tool room

Equipped tool room for complete tools assembly for injection Mould, Press tools & die casting machining of parts as per specifications.

3D Printing & Prototyping

3D printing is also one of part where we take review from customer before tooling using

FDM, SLA AND SLS.

Inspection Report

We have strict quality inspection team to effectively control the product from size shrinkage to appearance, color difference pirates and other issues.