* Services Home *

All you high-precision manufacturing requirements taken care of

We are committed to delivering exceptional quality and value to our clients with expertise in developing & manufacturing components for a wide variety of industry applications.

Core Services

We work closely with our clients to find best engineering solutions to develop new components or manufacture an existing one with precision, accuracy, reliability and repeatability.

VMC Milling

We manufacture complex Multi-Dimensional components requiring up to 4-Axis processes in conjunction with other machining steps.

CNC Turning

We make multi-dimensional turning parts, such as shafts, bolts, bushes, connectors, fittings and more in a variety of metals & plastics.

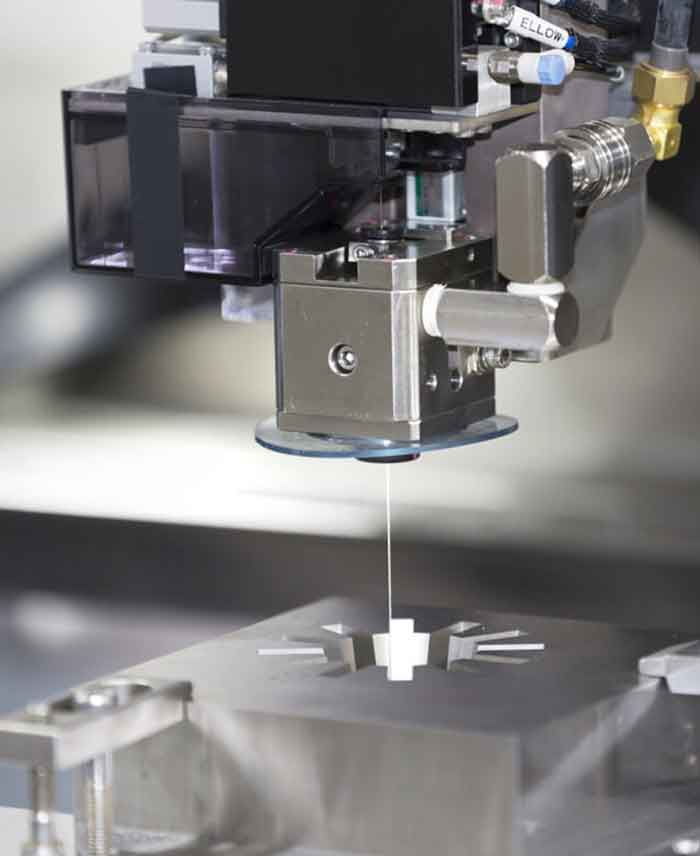

Injection/Die Molds

We make precision Injection/Die Molds for Plastics & Metal Pressure Casting for various industries, along with Jig Fixtures for Sheet Metal components.

Auxiliary Services

As an extension to our Core Services, we offer reliable services in other areas of pre & post manufacturing processes as well. Our objective is to offer our customers a one-stop-solution for most of their manufacturing demands.

EDM Wire-Cut

Die-Mold Fabrication

Laser

Cutting & Etching

Plasma Cutting

Metal Fabrication

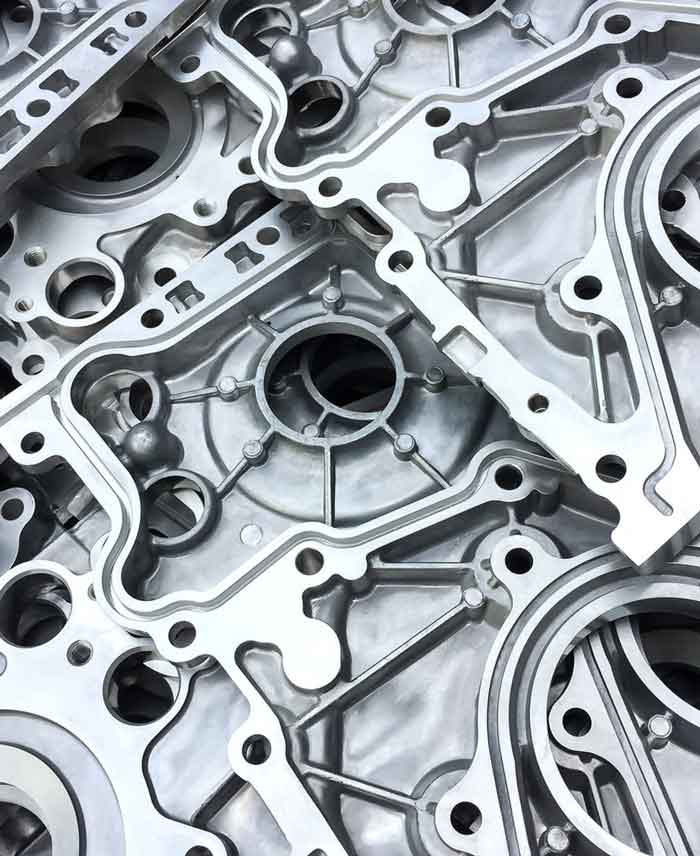

Metal Casting

Die-Mold Making

Coatings

Surface Treatment

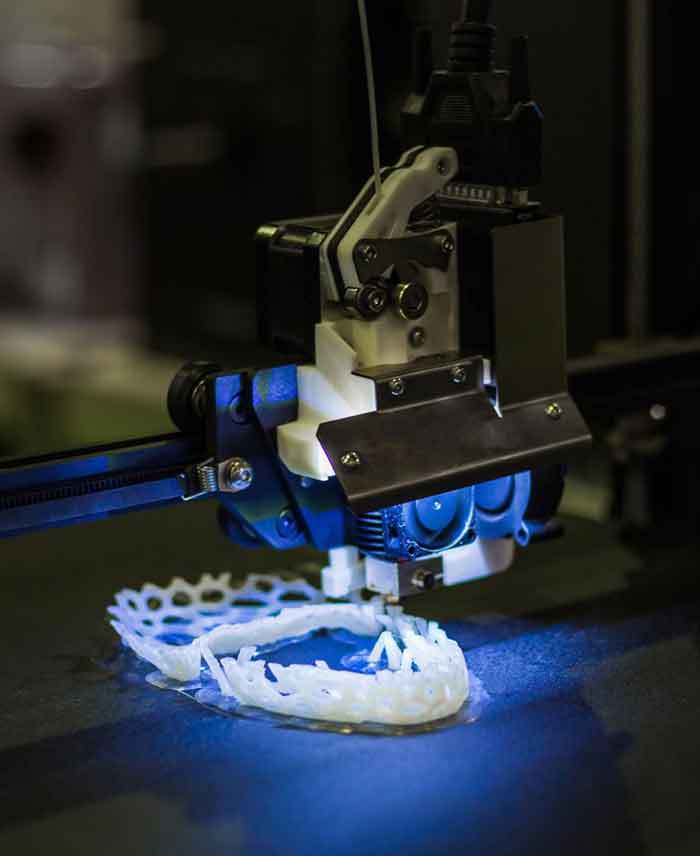

Prototyping

Product Development

Why choose BES?

At Babra Engineering Services (BES), we understand that every industry has unique requirements, and we are dedicated to providing customized solutions to meet the specific needs of our clients. Whether you need a single component or a large-scale production run, we have the expertise and capabilities to deliver the results you need.

So if you’re looking for a mechanical engineering company that can deliver high-quality, precision components with sophisticated technical features for your industry, look no further than BES. Contact us today to learn more about our services and how we can help you achieve your goals.

Precision & Repeatability

With experience, we have developed the ability to develop & manufacture extremely complex micro & large components having tight-tolerances with great accuracy and repeatability, with relative ease.

Export Quality

Having a stringent quality control process, reduces the overall rejection rate. The Rejection-Rate is as low as < 0.75% for some of our components. Translating to less production downtime.

Reliable Machinery

We have High-Precision reliable CNCs & VMCs from renowned Indian brands; purchased brand-new. Moreover, all our machinery is equally well maintained to ensure desired accuracy at all times.

Strong Team

Our workforce comprises of various skilled, qualified and experienced operators, quality control head and helpers etc;. Moreover, we have the capacity to expand our workforce rapidly as per demand.

Value Proposition

We offer good Value-For-Money proposition. Which means the quality of our products & services either meets or exceeds the clients expectations; translating to increased margins and profits.

One-Shop-Stop

Having strong collaborations with our sister-concerns & vendors, we are able to offer multiple engineering services from pre-manufacturing to post-manufacturing; such as material treatment, casting & assembly of components as a unit, to name a few.