* Fabrication & Coatings *

Developing & Machining

Complex parts with accuracy for diverse industry application

Our core area of expertise is product development & production of high-precision parts requiring subtractive methods on Vertical or Horizontal CNC machines.

CNC/VMC

Subtractive Machining processes

We work closely with our clients to understand their requirements and specifications for developing new components or manufacture an existing component with unparalleled precision, accuracy, reliability and repeatability.

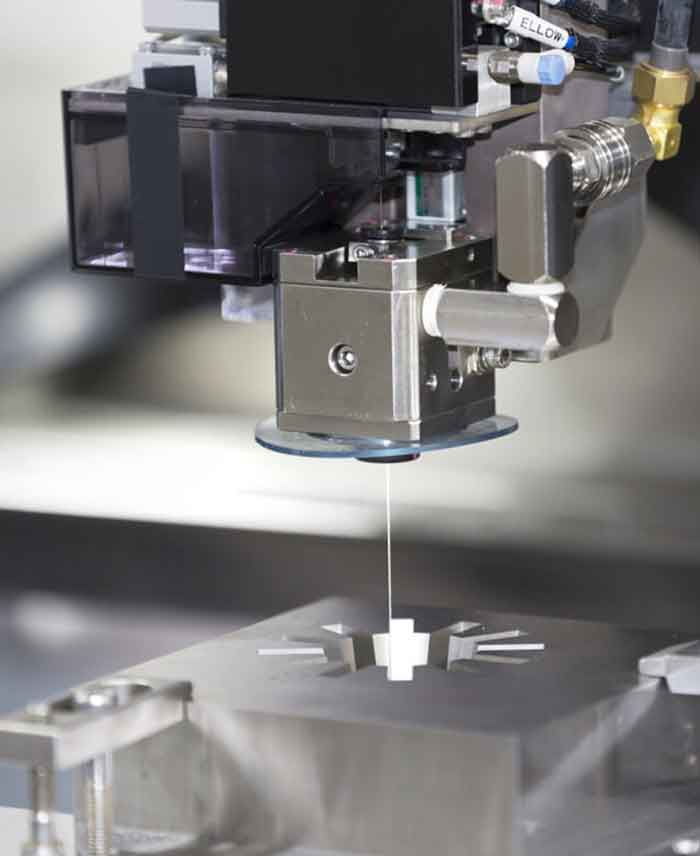

EDM - CNC Wire Cut

EDM (Electrical Discharge Machining) Wire Cut is a precision metal cutting process that utilizes electrical sparks to erode the material. A thin wire, typically made of brass or tungsten, is used as the electrode. This process is ideal for intricate and delicate cuts.

Laser Cutting

Laser cutting employs a high-powered laser beam to melt or vaporize the material, resulting in a precise cut. This process is widely used in various industries due to its versatility and accuracy.

CNC Plasma Cutting

The process involves passing an electrical arc through a nozzle, which ionizes the gas and forms the plasma jet. Plasma cutting is commonly used for industrial metal fabrication.

Hydro-Jet Cutting

The process involves forcing the water-abrasive mixture through a small nozzle at high speed, resulting in precise cuts.

Metal Coatings

There are various types of metal coatings available, each offering distinct properties and application methods.

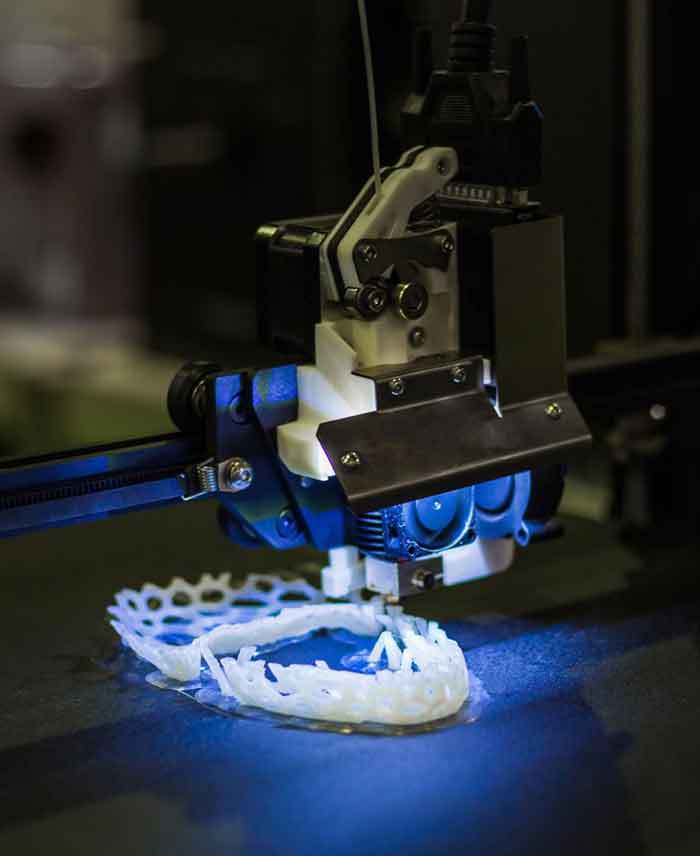

3D Printing - Rapid Prototyping

3D printing offers numerous benefits for rapid prototyping, including speed, cost-effectiveness, and design flexibility.

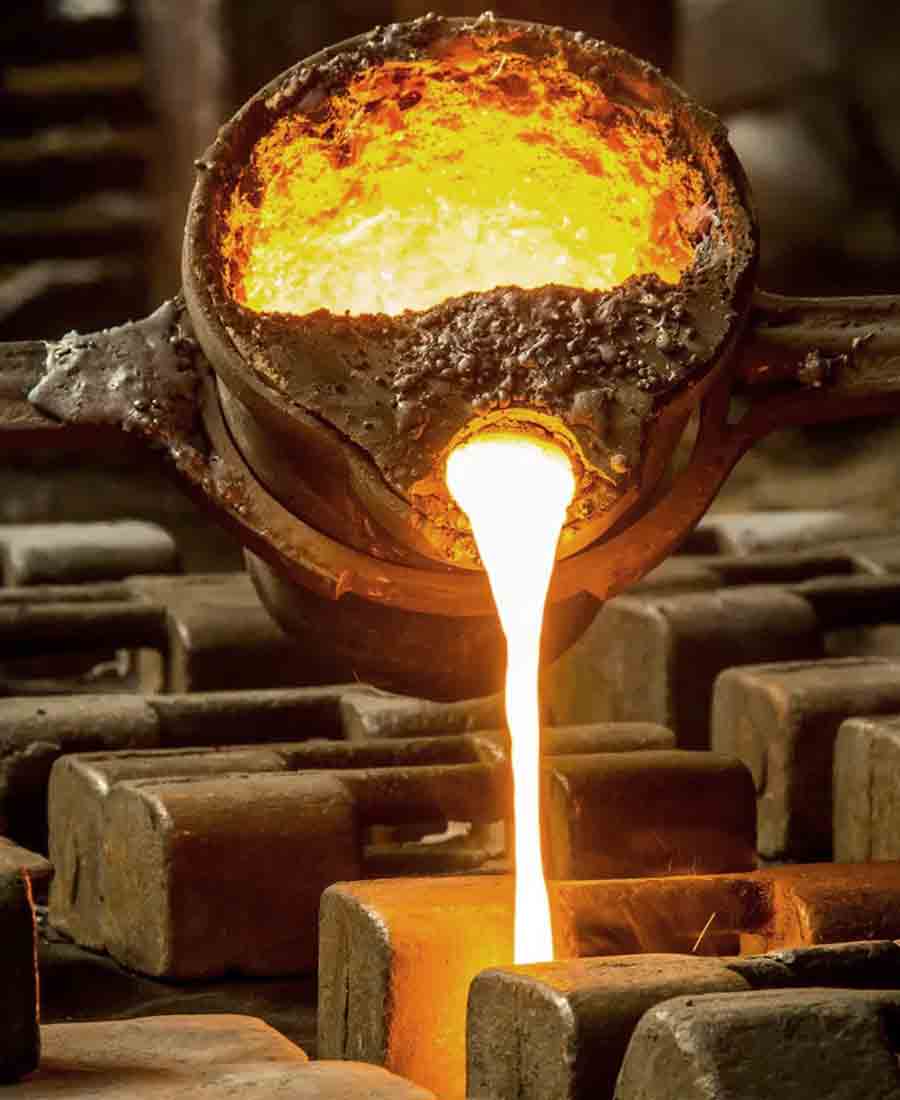

Metal Casting

It is a versatile technique that allows for the production of complex and intricate metal parts in various sizes and materials.

1. Sand Casting: Suitable for both ferrous and non-ferrous metals and is cost-effective for producing large and heavy parts.

2. Investment Casting: Allows for excellent dimensional accuracy and is ideal for producing complex shapes with fine details.

3. Die Casting: Widely used in industries such as automotive, electronics, and appliances for producing components with good surface finish and high production rates.

Auxiliary Services

Our Core-Services include Manufacturing of High-Precision CNC/VMC Components for multiple industry application. As a part of our commitment towards our valued clients, we provide the aforementioned services as a part of the manufacture process for specific components as per their requirements and order.

Note: Some of the listed services offered maybe a part of the ‘component manufacturing process’ only, and some may be available as a stand alone service. However, we’ll be glad to assist you with any of your queries. So, please get in touch with us for further information and/or to share details about your requirements.