- May 6, 2023

- BES

- 0

Sun on Earth!

Illuminating the Path to a Clean Energy Future

In the quest for sustainable and clean energy sources, nuclear fusion has long been hailed as the holy grail. The concept of harnessing the power of the sun, recreating the same fusion reactions that occur in the core of stars, holds the potential to revolutionize our energy landscape. In this article, we will delve into the fascinating world of nuclear fusion power, exploring its latest developments, remarkable progress in engineering, and the immense promise it holds for our future.

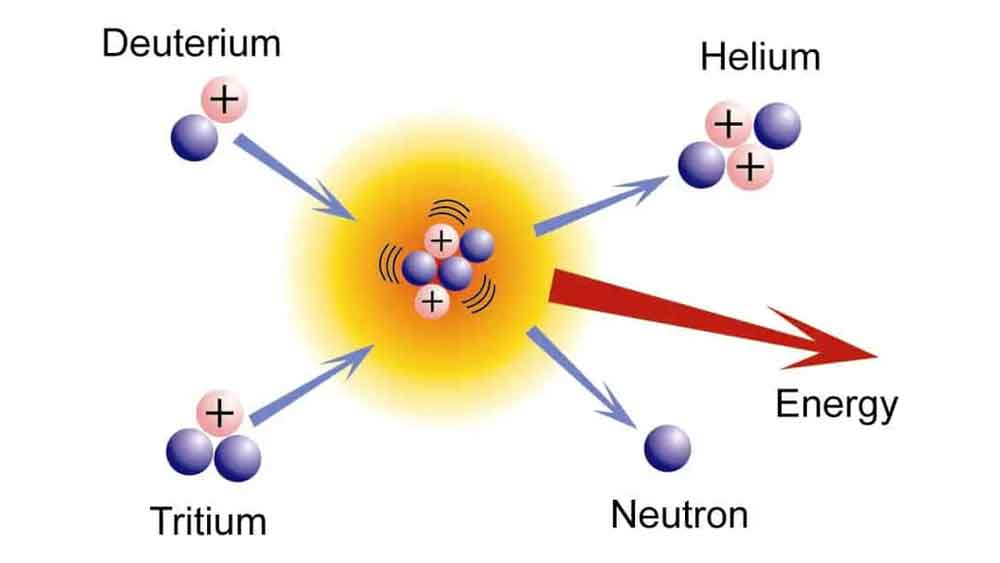

Nuclear fusion is the process of combining lightweight atomic nuclei, typically isotopes of hydrogen, to form heavier nuclei, releasing an enormous amount of energy in the process. While the scientific principles behind fusion have been known for decades, the engineering challenges to achieve controlled fusion reactions on Earth are immense.

Engineering Breakthroughs and Latest Developments:

1. Magnetic Confinement Fusion (MCF):

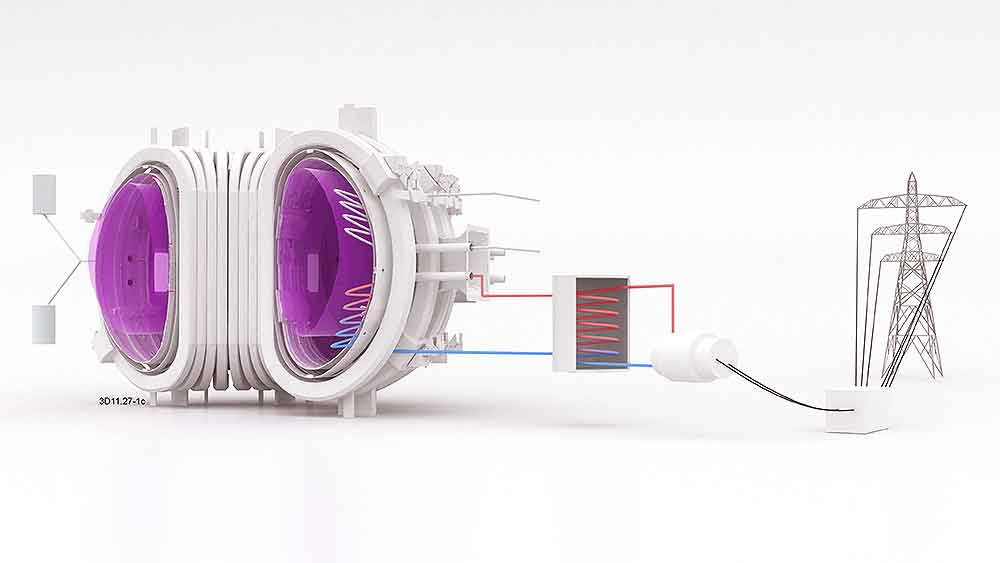

MCF is a leading approach to achieving controlled fusion reactions. Engineers have made significant advancements in designing and constructing fusion devices called tokamaks, which use strong magnetic fields to confine and control the plasma. These complex machines require advanced materials capable of withstanding extreme temperatures, powerful superconducting magnets for plasma containment, and sophisticated plasma control systems. Projects like ITER (International Thermonuclear Experimental Reactor) have reached crucial stages of construction, demonstrating the immense engineering expertise involved.

2. Inertial Confinement Fusion (ICF):

ICF utilizes powerful lasers or particle beams to rapidly compress and heat a small pellet of fusion fuel, triggering a self-sustaining fusion reaction. Engineers have been at the forefront of developing high-energy lasers, advanced target fabrication techniques, and precision diagnostics to understand and control the fusion process. Facilities like the National Ignition Facility (NIF) have achieved remarkable milestones in ICF research, narrowing the gap towards ignition and demonstrating the potential of this approach.

3. Novel Approaches and Technologies:

Engineering creativity is driving the exploration of alternative fusion concepts. Compact fusion reactors, such as the stellarator-based Wendelstein 7-X, require intricate engineering designs to achieve optimal magnetic confinement. Innovative fusion devices like the spherical tokamak are pushing the limits of compactness and efficiency. Private companies are also investing in fusion research, leveraging engineering expertise to develop novel technologies, such as magnetized target fusion and high-temperature superconductors, to accelerate progress.

Some Key-Developments in Engineering Challenges and Collaboration:

The pursuit of nuclear fusion power brings forth various engineering challenges that require multidisciplinary collaboration:

1. Materials Engineering:

Fusion reactions generate extreme heat and high-energy neutrons, necessitating the development of advanced materials capable of withstanding these conditions. Engineers are researching and testing novel materials, such as tungsten alloys and ceramic composites, that can endure prolonged exposure to high temperatures and neutron bombardment while maintaining structural integrity.

2. Plasma Control and Stability:

Maintaining stable and controlled plasma conditions is vital for achieving sustained fusion reactions. Engineers are continuously improving magnetic confinement systems and developing sophisticated control algorithms to optimize plasma stability, prevent instabilities, and maximize energy confinement.

3. Energy Conversion and Infrastructure:

The successful implementation of fusion power requires efficient energy conversion mechanisms and robust infrastructure. Engineers are working on developing advanced energy conversion systems, including innovative heat exchangers and turbine technologies, to convert the immense heat generated by fusion reactions into usable electricity. Additionally, the integration of fusion power plants with existing electrical grids and infrastructure presents engineering challenges that require careful planning and optimization.

The ITER project, involves the collaboration of 35 countries. These countries include the 27 member states of the European Union (EU), along with China, India, Japan, Russia, South Korea, and the United States.

Adding to our national pride, India joined the project as a full partner in 2005. As a partner, India contributes both financially and technically to the development of ITER. India’s participation in ITER highlights its commitment to research and development in the field of nuclear fusion and its aspirations to harness fusion power as a sustainable energy source. It also provides India with an opportunity to collaborate and share expertise with other nations involved in the project.

Meanwhile, we as an engineering company, may not have the capacity to contribute to the mentioned field currently; however, our long-term vision certainly aligns with the global pursuit for clean energy. At BES, we are committed to fostering a culture of innovation, collaboration, and continuous learning within our organization.